Operate with Efficiency

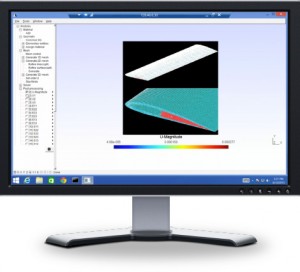

Popular in helicopter, air mobility (UAM, AAM, eVTOL), UAV, propeller, and wind turbine applications, VABS is a uniquely powerful approach to modeling composite blades and other slender structures (beams). VABS reduces analysis time from hours to seconds by quickly and easily achieving the accuracy of detailed 3D FEA with the efficiency of simple engineering models. With continuous US Army-funded development spanning over 30 years for performance and robustness, VABS is the tool of choice in the aerospace and wind energy industries for modeling complex composite rotor blades, wing section design, and simulating other slender structures. VABS can accurately compute the complete set of beam sectional properties for slender structures featuring arbitrary cross-sectional shape and materials. It can reproduce the accuracy of direct numerical simulation (DNS) using 3D FEA by explicitly modeling all the ply details of composite beams. VABS can also be used to calculate stresses, strains, and strengths. Users include multiple locations of the US Army, South Korea Agency for Defense Development (ADD), and many rotorcraft (helicopter, air mobility, UAV/UAS, propellers/fans) and wind turbine companies. VABS can be used to quickly provide accurate beam properties for third party comprehensive rotorcraft analysis codes Comprehensive Analytical Model of Rotorcraft Aerodynamics and Dynamics (CAMRAD) II and Rotorcraft Comprehensive Analysis System (RCAS). More details related to CAMRAD II and VABS can be found here.

The new capabilities of the latest release, VABS 4.1, are below. The manual for VABS 4.1 can be found here.

- Perform dehomogenization for multiple load cases in terms of forces and moments corresponding to the Euler-Bernoulli model and the Timoshenko model.

- Output the modes and corresponding ratios for failure criteria with identifiable modes such as failure criteria 1, 2, and 5.

- Provide documentation for the user-defined failure criterion capability.

- Enable users to suppress the output of other stress/strain files except for the average stresses/strains for each element in the ELE file.

- Remove damping input for no-damping analysis.

- Output the classical stiffness matrix and compliance matrix at the shear center.

- Enable comment lines in the inputs for better readability.

- Output the time and date the code is compiled and released.

- Provide simple instructions when VABS, VABS -h, or VABS -help is issued in the command line.

- Simplify the installation process without administrator privilege.

iVABS is an integrated framework developed by Purdue University with support from the US Army that can be used with the desktop version of VABS. iVABS enables VABS for design and optimization, parametric studies, uncertainty quantifications, etc. The release packages for either Windows or Linux and the complete documentation can be found at the iVABS website.

iVABS is an integrated framework developed by Purdue University with support from the US Army that can be used with the desktop version of VABS. iVABS enables VABS for design and optimization, parametric studies, uncertainty quantifications, etc. The release packages for either Windows or Linux and the complete documentation can be found at the iVABS website.

A powerful pre-processing tool called PreVABS is available as part of the iVABS framework. Developed by Purdue University, PreVABS is a completely new code, which has many improved capabilities. It is designed to reduce the workload of preparing input files of beam cross sections for VABS and to make the process automatic for design and optimization purposes. Cross sections with general and airfoil shapes can be created. VABS also directly interfaces with ANSYS, ABAQUS, and others.

VABS IS Also PART OF THE ALTAIR PARTNER ALLIANCE (APA).

VABS Interfaces with HyperMesh and OptiStruct.

User Spotlight

Advanced Technologies, Inc. (ATI) has been an avid user of VABS for 17 years. Both the Carson composite tail rotor (CTRB) and the Erickson Main rotor (CMRB) were ATI design programs that involved VABS, as well as many others. ATI has an extensive background in the design, analysis, fabrication and development of full and sub-scale advanced composite and metal rotor blades and precision machined rotor systems for both experimental and FAA testing. More details about ARI’s work with VABS can be found here.

“We started using VABS in 2008. Since that time, we have designed and fabricated approximately 25 different composite blade programs including scaled wind tunnel rotors, UAV propellers, full-scale experimental rotors, and also seven man-rated rotor blade designs. All of these programs started out with VABS and several more are on the horizon.”

Dave Pullman

Chief Structural Engineer/Engineering Manager

How can VABS help you?

- Unprecedented competitiveness through efficient, accurate modeling of real composite beams and other slender structures.

- Drastically reduced design cycle and time-to-market by saving orders of magnitude in design and analysis time.

- High fidelity results on a typical laptop computer, instead of a prohibitive detailed 3D FEA (even with heavy computing power).

- An enabling technology for nonlinear aeroelastic analysis of highly flexible structures.

1,000x FASTER

than 3D FEA for composite beam

Get the VABS Brochure

See the VABS Brochure for details about features and capabilities.

VABS Applications

MULTISCALE MODELING OF COMPOSITE BEAMS

- Helicopter rotor blades

- Wind turbine blades

- eVTOL, UAM, UAV, UAS, AAM, ODM, and ORB blades

- Propellers

- Landing gear

- High-aspect ratio wings

- Golf clubs

- Fishing rods

- Other slender composite structures

VIRTUAL TESTING OF COMPOSITE BEAMS

- Complete set of best multiphysical properties: needed for static/dynamic analysis using beam elements.

- Complete set of accurate multiphysical 3D fields: analyze under coupled effects of thermal, mechanical, and electromagnetic fields.

- Material properties: no restrictions on material properties and can handle any material, including isotropic, orthotropic, and anisotropic materials.

- Highly optimized for efficiency: ply-level details of real blades can be modeled in seconds.

- Directly integrated into other design environments, including ANSYS, ABAQUS, and others.

- Reap the full benefits of VABS using free companion code GEBT (1D beam analysis), which accepts the full stiffness matrix. PostGEBT, a postprocessor to GEBT is also available.

Unique Technology

VABS is a proven technology for an efficient alternative to detailed 3D FEA for composite beams. It is the only tool capable of rigorously decoupling an original 3D slender solid with complex microstructure (sophisticated cross section with or without spanwise heterogeneity) into a simple engineering beam model. As long as beam elements are used in the design (such as multibody dynamics simulation, aeroelastic simulation), VABS will compute the best stiffness constant (such as torsional stiffness) for the beam element. To deal with a composite wing/rotor, many 3D FEA rely on smearing many layers into one thick layer, which introduces significant errors and defeats the very purpose of being high fidelity. However, VABS can compute ply-level stress field without such approximations (achieving the accuracy as if 3D FEA models all the ply level details).