Enhance Efficiency of VABS with PreVABS

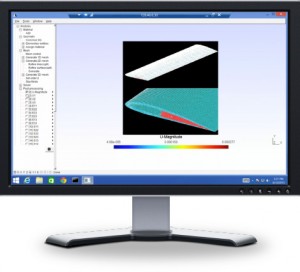

A powerful new standalone pre-processing tool called PreVABS is now available to enhance your use of VABS. PreVABS is designed to reduce the workload of preparing input files for VABS and to make the process automatic for design and optimization purposes.

Cross sections with general and airfoil shapes can be created. This replaces an earlier program, also called PreVABS, which has been discontinued and is no longer available. PreVABS is a completely new code, which has many improved capabilities. Unlike the previous program, PreVABS is now free and open source.

Some of the features of PreVABS include:

- Capability to create nose mass in an airfoil type cross section

- The post-processing function to visualize the recovered strains and stresses in Gmsh

- Capability to read stacking sequence code

- Design-oriented parametric input files to draw the cross section naturally

- Isolated material database file to enable reusability

- Global transformation capability to release the burden of calculating geometries by hand

PreVABS is available for free download through the Composites Design & Manufacturing HUB (cdmHUB.org), hosted by Purdue University. Please visit the PreVABS webpage on cdmHUB.org to download PreVABS or for additional information. You will also find a helpful discussion forum for technical questions about VABS and PreVABS.

VABS is a uniquely powerful approach to modeling composite blades and other slender structures (beams). VABS reduces analysis time from hours to seconds by quickly and easily achieving the accuracy of detailed 3D FEA with the efficiency of simple engineering models. With continuous development spanning over 20 years for performance and robustness, VABS is used in the aerospace and wind energy industries for modeling complex composite rotor blades, wing section design, and simulating other slender structures. VABS can accurately compute the complete set of beam sectional properties for slender structures featuring arbitrary cross-sectional shape and materials. It can reproduce the accuracy of direct numerical simulation using 3D FEA by explicitly modeling all the ply details of composite beams. In addition to PreVABS, VABS directly interfaces with ANSYS, ABAQUS, and others.

How can VABS help you?

- Unprecedented competitiveness through efficient, accurate modeling of real composite beams and other slender structures.

- Drastically reduced design cycle and time-to-market by saving orders of magnitude in design and analysis time.

- High fidelity results on a typical laptop computer, instead of a prohibitive detailed 3D FEA (even with heavy computing power).

- An enabling technology for nonlinear aeroelastic analysis of highly flexible structures.

1,000x FASTER

than 3D FEA for composite beam

Get the VABS Brochure

See the VABS Brochure for details about features and capabilities.

VABS Applications

MULTISCALE MODELING OF COMPOSITE BEAMS

- Helicopter rotor blades

- Wind turbine blades

- Propellers

- High-aspect ratio wings

- Golf clubs

- Fishing rods

- Other slender composite structures

VIRTUAL TESTING OF COMPOSITE BEAMS

- Complete set of best multiphysical properties: needed for static/dynamic analysis using beam elements.

- Complete set of accurate multiphysical 3D fields: analyze under coupled effects of thermal, mechanical, and electromagnetic fields.

- Material properties: no restrictions on material properties and can handle any material, including isotropic, orthotropic, and anisotropic materials.

- Highly optimized for efficiency: ply-level details of real blades can be modeled in seconds.

- Directly integrated into other design environments, including ANSYS, ABAQUS, and CATIA.

- Reap the full benefits of VABS using free companion code GEBT (1D beam analysis), which accepts the full stiffness matrix. PostGEBT, a postprocessor to GEBT is also available.

Unique Technology

VABS is a proven technology for an efficient alternative to detailed 3D FEA for composite beams. It is the only tool capable of rigorously decoupling an original 3D slender solid with complex microstructure (sophisticated cross section with or without spanwise heterogeneity) into a simple engineering beam model. As long as beam elements are used in the design (such as multibody dynamics simulation, aeroelastic simulation), VABS will compute the best stiffness constant (such as torsional stiffness) for the beam element. To deal with a composite wing/rotor, many 3D FEA rely on smearing many layers into one thick layer, which introduces significant errors and defeats the very purpose of being high fidelity. However, VABS can compute ply-level stress field without such approximations (achieving the accuracy as if 3D FEA models all the ply level details).