Inha University Uses SwiftComp Simulation Software for Virtual Testing of Woven and Braided Composites

Inha University Uses SwiftComp Simulation Software for Virtual Testing of Woven and Braided Composites

The tool helps mitigate the burden of costly experiments and confirm accuracy

West Lafayette, Indiana (USA) – AnalySwift, LLC, a provider of efficient high-fidelity modeling software for composites, announced today that Inha University in Incheon, South Korea, is participating in its Academic Partner Program (APP), and it is leveraging its SwiftComp simulation software for virtual testing of braided and woven composite materials. The work is part of the research being conducted in the Department of Mechanical Engineering.

The APP offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers, and faculty can leverage the tools in their academic research.

The SwiftComp program general-purpose multiscale modeling code that enables users to perform efficient and accurate modeling of composites and other advanced materials (metamaterials, architected materials, porous materials, tailorable composites etc.). It can be used either independently as a tool for the virtual testing of composites or as a plugin to power conventional FEA codes with high-fidelity multiscale modeling for composites.

“We are pleased to hear about the work being done by the Inha University in the area of woven and braided composites and are happy to learn SwiftComp has helped in their efforts,” said Allan Wood, president & CEO of AnalySwift. “As a versatile general-purpose, truly multiscale modeling code for composites, it directly and seamlessly links detailed microstructure and structural behavior for composite structures including beams, plates/shells, and 3D structures.”

“SwiftComp is an advantageous interface with third-party tools, such as Ansys and Abaqus,” said Vivek Kumar Dhimole, PhD student in the Solid Mechanics Laboratory working under the direction of professor Chongdu Cho on researching multiscale modeling of the composite structures. “We work on woven and braided composites. Specifically, we study polymer matrix composites (PMC) and ceramic matrix composites (CMC), and we use SwiftComp to find the stiffness of materials that will mitigate the burden of costly experiments. The tool is also used for the homogenization of composites. SwiftComp helps us to compare our calculated results and confirm their accuracy.”

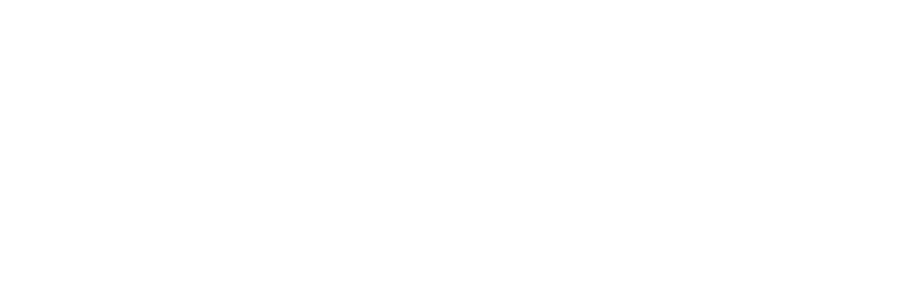

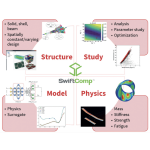

Mesomodel of Braided RVE- Dehomogenized Behavior (image provided by Inha University).

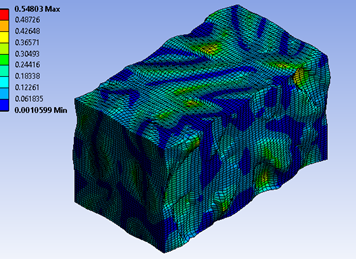

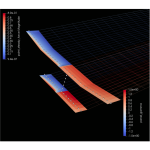

Macro Model Analysis of Plate with Hole Structure (image provided by Inha University).

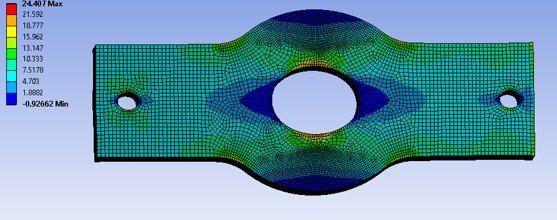

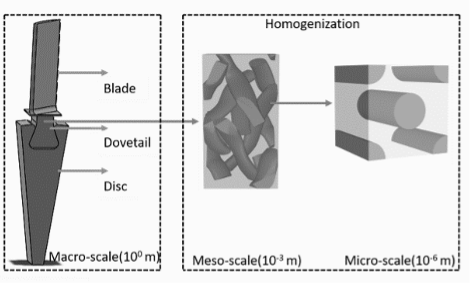

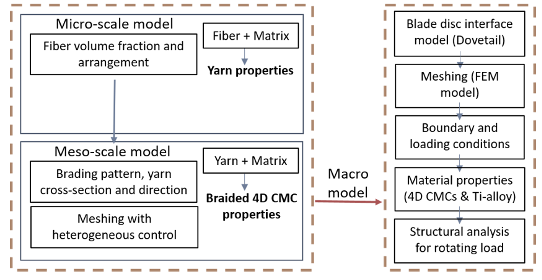

“The braided anisotropic structure above is homogenized to check the working of SwitComp. These structures can be used at the joint of two components for high out-of-plane strength for the aero, automobile, and marine industries” continued Dhimole. “Our research can help with homogenization and calculation of mechanical properties. SwiftComp is used for checking the accuracy of results. “In the research (https://doi.org/10.1007/s42405-021-00421-8), braided CMC dovetail mechanical properties are calculated and checked by SwitComp. Those are used for macrostructure analysis of homogenized turbine blade dovetail to suggest the CMC material for turbine blade dovetail as shown below in Figures.”

Multi-scale modeling of dovetail(ref.-https://doi.org/10.1007/s42405-021-00421-8)

Schematic of modeling and analysis (ref- https://doi.org/10.1007/s42405-021-00421-8)

“SwiftComp saves hours in computing time and resources with accuracy comparable to modeling all the microstructural details using 3D FEA,” said Dr. Wenbin Yu, CTO of AnalySwift. “It can also predict accurate local stresses and strains in the microstructure for the purpose of predicting strengths and thermal expansion of composites.”

The full press release is also available here.

About AnalySwift

AnalySwift, LLC is a composite simulation software provider, enabling an unprecedented combination of efficiency and accuracy, including multiphysics structural analysis and micromechanics modeling. Based on cutting-edge university technology, AnalySwift’s powerful solutions provide customers a competitive advantage through drastic reductions in engineering time, virtual testing earlier in the design process, and handling more complex composite structures. The company’s technologies deliver the accuracy of detailed 3D FEA at the efficiency of simple engineering models, cutting analysis time by orders of magnitude. Purdue Research Foundation licenses SwiftComp. VABS is licensed by Utah State University, Georgia Institute of Technology, and Purdue University. Find out more at analyswift.com.

Media Contact: Allan Wood, (801)-599-5879, info@analyswift.com, www.analyswift.com