Seoul National University Leverages VABS for Accurate Simulation of Helicopter Rotor Blades

May 12, 2020

WEST JORDAN, Utah (USA) – AnalySwift, LLC, a provider of efficient high-fidelity modeling software for composites, announced today Seoul National University is leveraging its VABS software in the design and analysis work on its helicopter rotor blades, including the Seoul National University Flap (SNUF) Blade.

“The university joined AnalySwift’s Academic Partner Program in 2019 and we are excited to follow the work being done on composite rotor blades and similar structures,” said Allan Wood, president & CEO of AnalySwift. “The Academic Partner Program offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers, and faculty can leverage the tools in their academic research.”

“In our Active Aeroelasticity and Rotorcraft Lab (AARL) at Seoul National University, coupled analysis using computational structural dynamics (CSD) and computational fluid dynamics (CFD) is being conducted to verify for analysis-experiment correlations to solve aeroelastic problems,” said Dr. SangJoon Shin, Professor of Aerospace Engineering. “For example, rotorcraft aeroelastic analysis, CSD/CFD coupled analysis, multidisciplinary design optimization of the active rotor blade such as active trailing edge flaps are being studied. Further, we study fixed aircraft flutter analysis for unmanned vehicles, as well as structural analysis for highspeed vehicles, launch vehicles, and flexible structures for the bio-inspired flapping-wing micro air vehicle.”

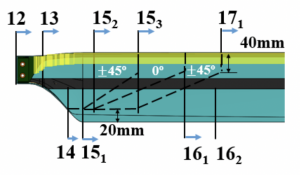

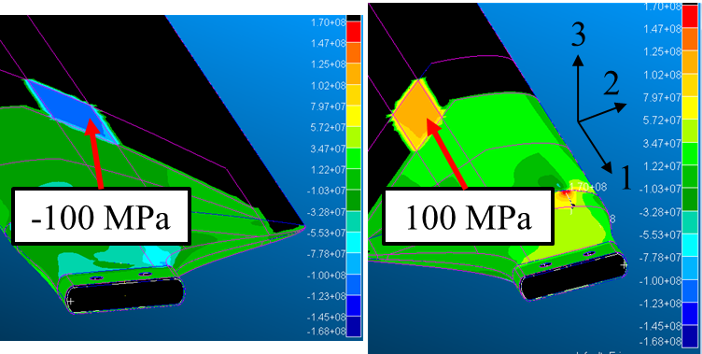

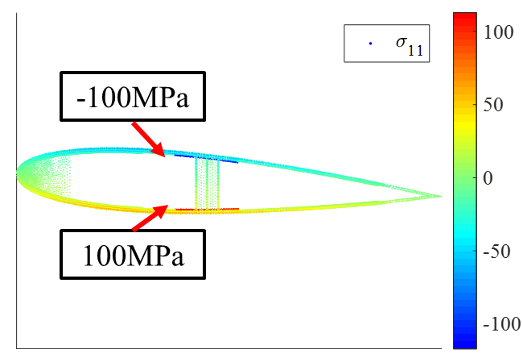

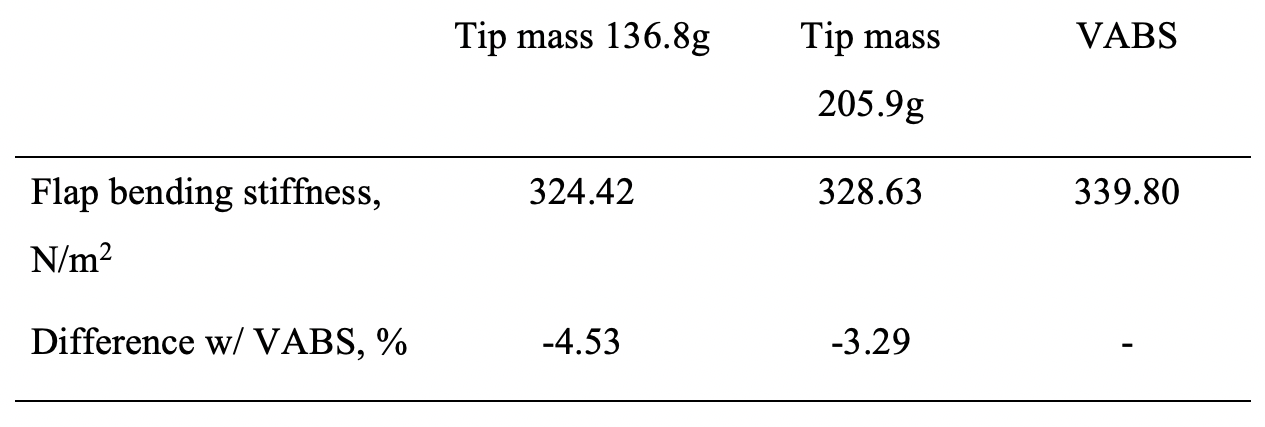

One of AARL’s projects is an experimental evaluation on a mach-scaled SNUF blade for active vibration control. The research group uses VABS along with other tools for its structural analysis and design verification, including calculating 2D cross-sectional analysis properties. VABS is also one of the tools used to calculate the structural safety margin. The researchers found VABS sectional analysis to be accurate when compared with more time consuming and computer-intensive 3D analysis methods.

“VABS allows the multidisciplinary design of a composite rotor blade in a very short time,” Shin said. “We designed an active-trailing edge flap blade with glass- and carbon-fabrics with epoxy. The VABS analysis tool utilized in the design program predicted the mass and stiffness properties of the fabricated blade within 5% discrepancies.“

The VABS program is a general-purpose cross-sectional analysis tool for computing beam properties and recovering 3D stresses and strains of slender composite structures. It rigorously models composite helicopter and wind turbine rotor blades, as well as other slender structures, such as propellers, landing gear, high-aspect ratio wings, and golf club shafts. As a versatile tool, VABS saves orders of magnitude in computing time without a loss of accuracy so engineers can consider more design options and arrive at the best solution more quickly. This allows researchers to accelerate project completion while reducing costs.

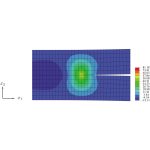

Stress recovery comparison in X153 section.

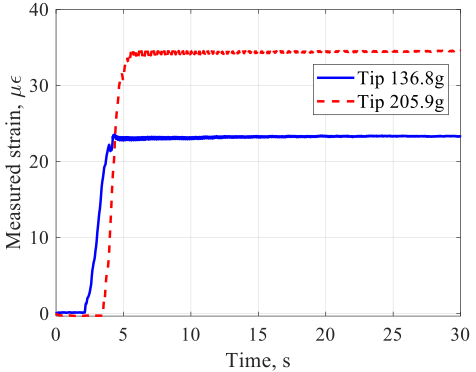

Tip load experiment results

The full press release is available here.

About AnalySwift

AnalySwift, LLC is a provider of composite simulation software, which enables an unprecedented combination of efficiency and accuracy, including multiphysics structural analysis and micromechanics modeling. Drawing on cutting edge university technology, AnalySwift’s powerful solutions provide customers a competitive advantage through drastic reductions in engineering time, virtual testing earlier in the design process, and handling of more complex composite structures. The company’s technologies deliver the accuracy of detailed 3D FEA at the efficiency of simple engineering models, cutting analysis time by orders of magnitude. SwiftComp is licensed from Purdue Research Foundation. VABS is licensed from Utah State University, Georgia Institute of Technology, and Purdue University. AnalySwift is a member of the Institute for Advanced Composites Manufacturing Innovation (IACMI). Find out more at analyswift.com.

Media Contact: Allan Wood, (801)-599-5879, info@analyswift.com, www.analyswift.com